The firepower of Yanban remains unchanged, with 17 ceramic enterprises building/igniting/signing 20 production lines in August. And just from August 23rd to 29th, six new production lines were added.

Liang Bohao, General Manager of Laideli, believes that 90% of the opportunities for Yanban are in industries such as home furnishings and furniture.

However, an industry insider revealed that due to ink technology issues, some rock panel factories are unable to supply, and some companies are hesitant to accept orders for dark rock panels. At present, dark rock slabs are turning to dry grain polishing, but its cost is about four times that of full glaze polishing, causing a sharp increase in cost pressure for rock slab enterprises.

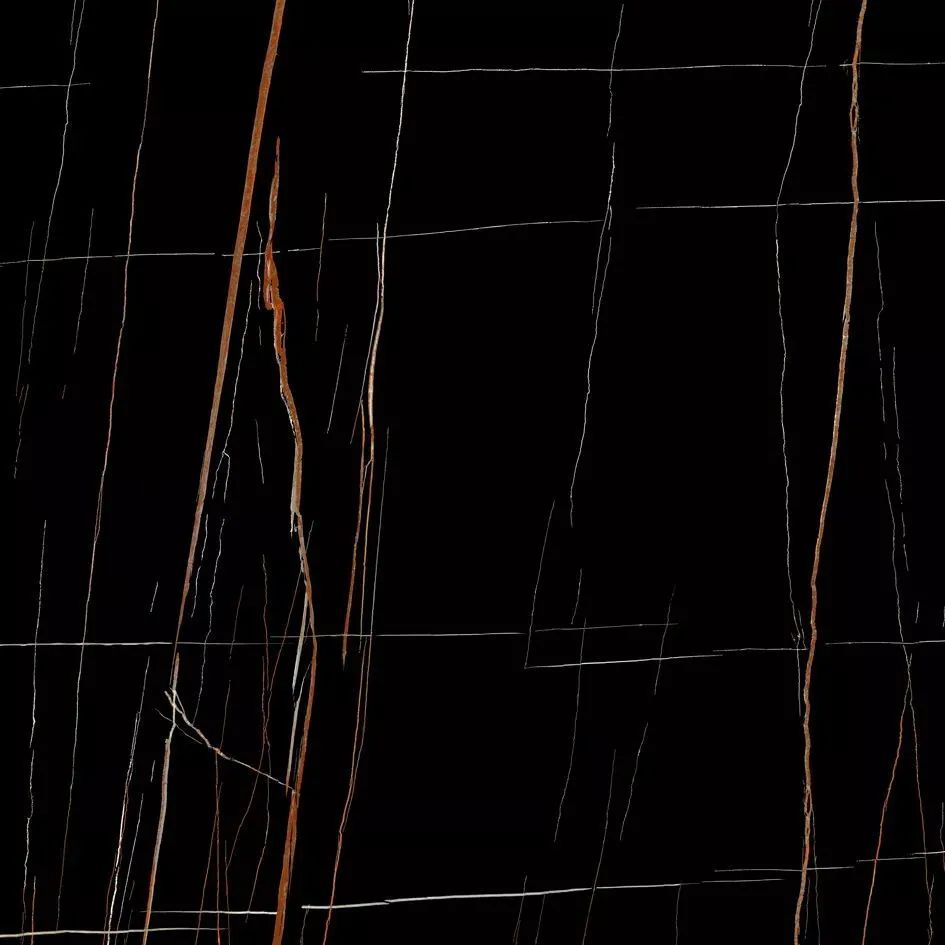

Recently, an interview with Tao Chengjun found that a domestic dry grain enterprise has overcome the production difficulties of Laurent black gold, velvet and other rock slabs, with an excellent rate of over 97%. Not only can it solve the problem of water ripples, "it will replace full glaze in the future," but it can also help the enterprise save millions of yuan annually.

.

Rock board enterprises dare not take orders

Domestic dry granules break through world challenges

According to multiple rock panel companies, due to the fact that the colors and specifications of home application rock panels come from stone, the currently popular rock panels are mainly black and white gray series, while the black series is mainly Lauren black gold.

Su Cheng, General Manager of Longyang Dried Granules Sales, believes that due to the fact that home furnishings mainly rely on matte surfaces, whether it is on the wall, below the ground, or even in conjunction with the style of home furnishings, kitchen and bathroom, matte surface rock slabs are more suitable. Bright surface rock slabs are mainly above the wall and have less flooring.

However, some companies have reported that they are very afraid of receiving related orders. "The general manager of a certain rock board company told me that he has taken many orders for dark rock boards, but their factory is unable to provide products, and they dare not take them in the future

The color and strength of the dark black rock slab are quite challenging for the process technology, and ordinary ink is prone to problems such as nozzle blockage, making it difficult to meet the demand. At the same time, rock slabs usually have high requirements for processing performance, especially for slabs below 6mm. Traditional water glaze can have a significant impact on the brick shape, so dark rock slabs such as Lauren Black Gold have switched to dry grain polishing.

Dry particle polishing can be divided into wet and dry methods. Industry insiders believe that wet dry particle polishing is suitable for producing light colored large boards. Dark color means that there will be more ink jet water. Due to the oily nature of ink, using wet dry particle polishing to produce dark colored bricks will result in ink discharge and glaze peeling, leading to some defects on the glaze surface. So, currently, the black rock slab basically adopts dry method dry particle throwing technology.

According to Su Shihong, Chairman of Longyang Dried Granules, Longyang Dried Granules has overcome this world problem in May this year, and its dry particle throwing products have successfully helped multiple rock sheet companies produce Laurent black gold rock sheets. At present, more than 10 rock slab production lines, including Xinmingzhu, Jinjin, and other enterprises, are using Longyang's large slab dry particle throwing

Replacing Full Glaze to Solve Water Ripples

In addition, another urgent issue for rock slabs is the water ripple problem.

At the Architecture Institute Forum held at the 2020 Foshan Tanzhou Ceramic Exhibition, Wang Yongqiang, a director of the Interior Design Branch of the Chinese Architecture Society and the director of the Shenzhen Architecture Design and Research Institute, reported that some high gloss and mirror like stone slabs in large public decoration projects are prone to flatness problems under natural light testing.

According to industry insiders' analysis, the flatness of rock slabs using fully glazed tiles is poor and prone to water ripples. In order to improve the added value of rock slabs, dry grain polishing is becoming more and more widely used. Recently, Taochengjun discovered that the 750 with new processes such as soft light and dry grain semi polishing × 1500 (mm) products will soon emerge in the northern market.

Su Cheng believes that "now that fully glazed tiles have been made for so many years, the amount used is definitely very large. Its advantages include cheap price and wider application range. However, dry grain polishing is prepared for the next step of banning fully glazed tiles

According to his analysis, full glaze has several drawbacks. The first one is that its hair color and texture design are not as clear, and the sense of lines, layers, and three-dimensional sense is not as strong. Secondly, full glazing cannot solve the flatness problem and achieve a mirror effect. Thirdly, full glaze polishing cannot produce dark rock slabs, and there may be yellow and white edges after polishing. Fourthly, in terms of physical properties, the practical application environment has high requirements for acid and alkali resistance, and there is a problem of acid and alkali resistance in fully polished glaze.

Dry grain polishing is 4 times more expensive than full glaze polishing

Up to 99% excellent rate to reduce costs

However, to replace full glaze with dry grain polishing, issues such as cost and superiority still need to be addressed. Hu Zhen, General Manager of Sales at Xinzhilian, told Tao Chengjun that one of the reasons for the slow promotion of "dry grain half throw" in the industry in the past was the high cost.

Whether it is wet or dry method, the price of domestic dry particles is about 3-4 times that of the glaze polishing scheme, with a glaze polishing price of about 3000-4000 yuan/ton. However, the price of domestic dry particles is about 10000 yuan/ton, and the price of foreign dry particles is about 12000 yuan/ton.

According to industry insiders, the dry method requires one kilogram of dry particles per square meter, while the wet method only requires about half of the amount of dry particles. The cost of wet dry particle polishing is lower, and the mirror effect is not as good as dry dry particle polishing, but it also exceeds full glaze polishing.

At present, domestic dry grain enterprises are striving to reduce costs to replace imports. According to Su Shihong, "The customer requires that all indicators of our dry granule products exceed those of imports, and the price should be relatively cheap. We meet the customer's requirements. The price is cheaper, and we have achieved indicators such as acidity, alkalinity, color, and surface effect

According to the introduction, the excellent rate of Longyang's large board dry particle throwing has reached over 97%, even 99%

According to an industry insider's calculation, a piece of rock slab is priced at several hundred yuan. If the premium rate is increased by two points, calculated at 33000 square meters per day, it can save at least 3 to 4 million yuan per year.

Common for dry and wet dry particle throwing

First to launch velvet dry pellets

In addition to its price advantage, Su Shihong believes that the most challenging aspect at present is the universal use of dry and wet methods for large board dry particle throwing. At present, dry pellet enterprises in Italy and Spain are unable to achieve universal use in the market. We have already produced large quantities of dry and wet methods

In addition to the hot sales of black and white gray series rock slabs, "the main trend is still rock slabs with matte surfaces, or velvet and other 30 to 40 degree soft light rock slabs

Velvet is a material that has been widely used and searched for in recent years. Sofas or bed decorations made of velvet can create luxurious visual effects in homes.

Su Shihong said that velvet and golden velvet dry grain rock throwing boards have several characteristics. Firstly, they have a relatively warm feel, secondly, they solve the problem of poor color and transparency of antique system products, and thirdly, their Mohs hardness is above level 6, their wear resistance reaches level 4, and their glossiness is 40 degrees.

In terms of dry particle throwing applications, it is revealed that "there are more than 10 domestic enterprises that have developed dry and wet dry particle throwing methods. We have successfully mass-produced them and have cooperated with 80-90% rock sheet factories

And in the process of cooperating with Gold Medal Asia, Longyang Dried Granules also eliminated many competitors. "Last year, seven or eight factories conducted wet dry particle throwing tests at Gold Medal. There were five or six companies in China, and after our pilot test was completed, Gold Medal placed an order for us to deliver the goods, but the pilot test of two international enterprises was not completed

Behind the achievements, Su Shihong said, "Long Yang has been working on dry granules since 1998, specializing in research and development and production for 22 years. In the second half of 2018, Long Yang began to self adjust and focus on challenging difficult new technologies

Longyang Gan Li Tan Zhou Exhibition Booth

Not long ago, Longyang Ganli reached a strategic cooperation with Guoci Kanglitai. Guoci Kanglitai is a holding subsidiary of Shandong Guoci Functional Materials Co., Ltd., a listed company. Kanglitai has an annual production capacity of 10000 tons of ceramic ink, 10000 tons of ceramic infiltrated ink, 8000 tons of pigments, and 10000 tons of glaze, ranking among the top in the domestic ceramic raw material industry. Its independent research and development, production, and sales of two high-end brands, "Botao Ink" and "Kanglitai Color Glaze", have been recognized in the industry.

It is reported that Longyang Dry Granules focuses on technological innovation and has strong research and development capabilities in frits and glazes. It is equipped with four energy-saving frit kilns and more than ten advanced dry particle production lines, with an annual output of over 60000 tons. Its products are best-selling in both domestic and international markets, and have gained recognition from the vast market and industry due to their advantages of stable quality, good hair color, and high quality rate.

In addition to dry grain polishing, in 2017, Longyang also increased its investment in the research and development and market promotion of glaze products. There are currently products with full polishing glaze, diamond glaze, soft glaze, forged glaze, antique glaze, anti slip glaze, anti slip dry grain, dry grain semi polishing, precision carving protective glaze, metal glaze, and other special materials.